04/10/2024

The following terms have been compiled due to the nomenclature of our offering at Envision, the nature of the No Molds Required fabrication technology and simply from the dialogue that we have had with our clients over the past two decades! When talking with one of our sales people or design engineers, you may just hear a few of these terms when discussing your custom plastic enclosure project!

NMR (Fabrication) – No Molds Required. Our manufacturing process is dubbed this since all of our parts are fabricated with No Molds Required.

ACM – Aluminum Composite Material. A unique aluminum double laminated polyethylene material that is very light weight, sturdy, and come with a pre-painted finish.

Shablona – A fixture made to hold a CNC Milled part that required routing from both sides or faces of the part.

Facetting – Adding a small radius or chamfered edge to a part.

Boss – A plastic cylindrical plastic standoff that often contains a threaded insert. Used to mount internal enclosure components like PCBs and LCDs.

HIPS – High Impact Polystyrene. We stock this economical UL94-HB rated material in black 3mm, 4mm, 6mm, and 10mm.

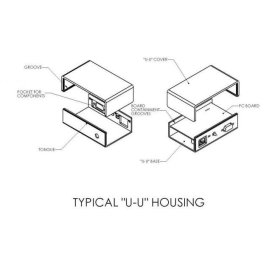

UU Box – This enclosure concept consists of two U-Formed parts that snap together as a two piece enclosure assembly through tongue and groove techniques. Some would also call this a “clam shell” housing.

Facer – the thin layer of aluminum that sandwiches ACM’s polyethylene core. Usually comes in .008 thick and .012 thick. Envision requires .012 thick facers on formed parts.

CMYK – A printing color scheme model of combining ink pigments (Cyan, Magenta, Yellow, and Key (black)). These colors mix to form the proper ink color.

Bonding – Another term for solvent welding. Depending on the plastic material used (ABS, HIPS, Polycarbonate), we use the appropriate solvent to melt/bond/weld joints and plastic standoffs in proper locations enhancing the functionality of the enclosure.

Fire Rating – There are frequent scenarios in which enclosure materials need to meet a certain fire rating to be compliant in their industry. Each industry has its own requirements specific to the electronic housing being used. For example, most medical enclosures need a UL94-V0 rating (or above) which means: Vertical Burn Test; Burning stops within 10 seconds, NO flaming drips are allowed. Other material fire ratings, such as UL94-HB, are also commonly used at Envision and have similar test results which must meet select industry criteria.

If you have any questions about what you have read - feel free to contact us!